Hardness testing is one of the quickest and easiest ways to check product quality or process results, with very little sample prep needed and simple tests that can be taught in a matter of minutes (you can read more about metallographic neophytes learning the AMH55 in an earlier blog post), but one critical step in the testing process is checking the calibration of the instrument. To verify the hardness test results are, in fact, accurate, the hardness tester must be proved to be accurate. Various standards for hardness testing have various frequencies for checking calibration, but all of them require it up front. Checking the calibration of a hardness tester is as simple as using a test block. This is a block with a certified hardness number at a certain force for a certain type of hardness test. Figuring out what those levels are, however, can get confusing.

Hardness testing is one of the quickest and easiest ways to check product quality or process results, with very little sample prep needed and simple tests that can be taught in a matter of minutes (you can read more about metallographic neophytes learning the AMH55 in an earlier blog post), but one critical step in the testing process is checking the calibration of the instrument. To verify the hardness test results are, in fact, accurate, the hardness tester must be proved to be accurate. Various standards for hardness testing have various frequencies for checking calibration, but all of them require it up front. Checking the calibration of a hardness tester is as simple as using a test block. This is a block with a certified hardness number at a certain force for a certain type of hardness test. Figuring out what those levels are, however, can get confusing.

ASTM E18 is a standard that goes into detail about Rockwell hardness testing, and it is helpfully straightforward in its block selection. The instrument must be verified daily with a test block within 15 Rockwell points of the test specimen. This means if your sample should be 40 on the Rockwell C scale, your test block needs to be between 25 and 55 on that same scale. If you do not have an appropriate test block, you can use two test blocks, one higher and one lower, to verify the calibration.

While Rockwell testing is the most common type of hardness testing, other test methods such as Brinell, Knoop, or Vickers may also be used. The standards associated with these tests are not nearly so straightforward in their test block selection. Various standards, such as ASTM E10 (Brinell) and ASTM E384 and ASTM E92 (Knoop and Vickers) specifically call for a test block at «approximately the same hardness value as the material to be measured,» which is not very specific at all. While ASTM E384 does include a table with hardness ranges, these ranges have hundreds of levels of variation. What, therefore, does «approximately» mean?

The most important thing to remember when trying to pick an appropriate test block is that you are actually verifying the calibration of the instrument and not the material you are testing. A test block that matches your sample exactly is not as important as being able to confirm that your instrument is functioning appropriately in the range you are testing at. This is why LECO suggests keeping a set of test blocks covering the range of your common materials tested, and when you have concerns about a test block being «approximately» close enough, test two blocks instead, one above and one below your sample, to confirm the calibration over the entire range.

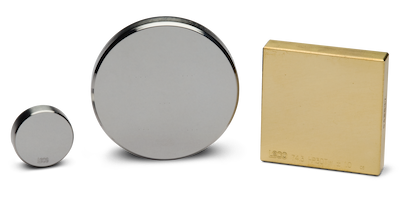

Starting with a good standard test block is critical to confidence in your results, and that is why LECO offers a wide variety of test blocks to match all your laboratory’s needs. We can accommodate nearly any request for hardness test blocks for type, indenter, hardness, and load. Our commitment to quality extends to all LECO-branded consumables, standards, and reference materials.

Request a Consumables Catalogue today to see what you’ve been missing.

Request a Consumables Catalog